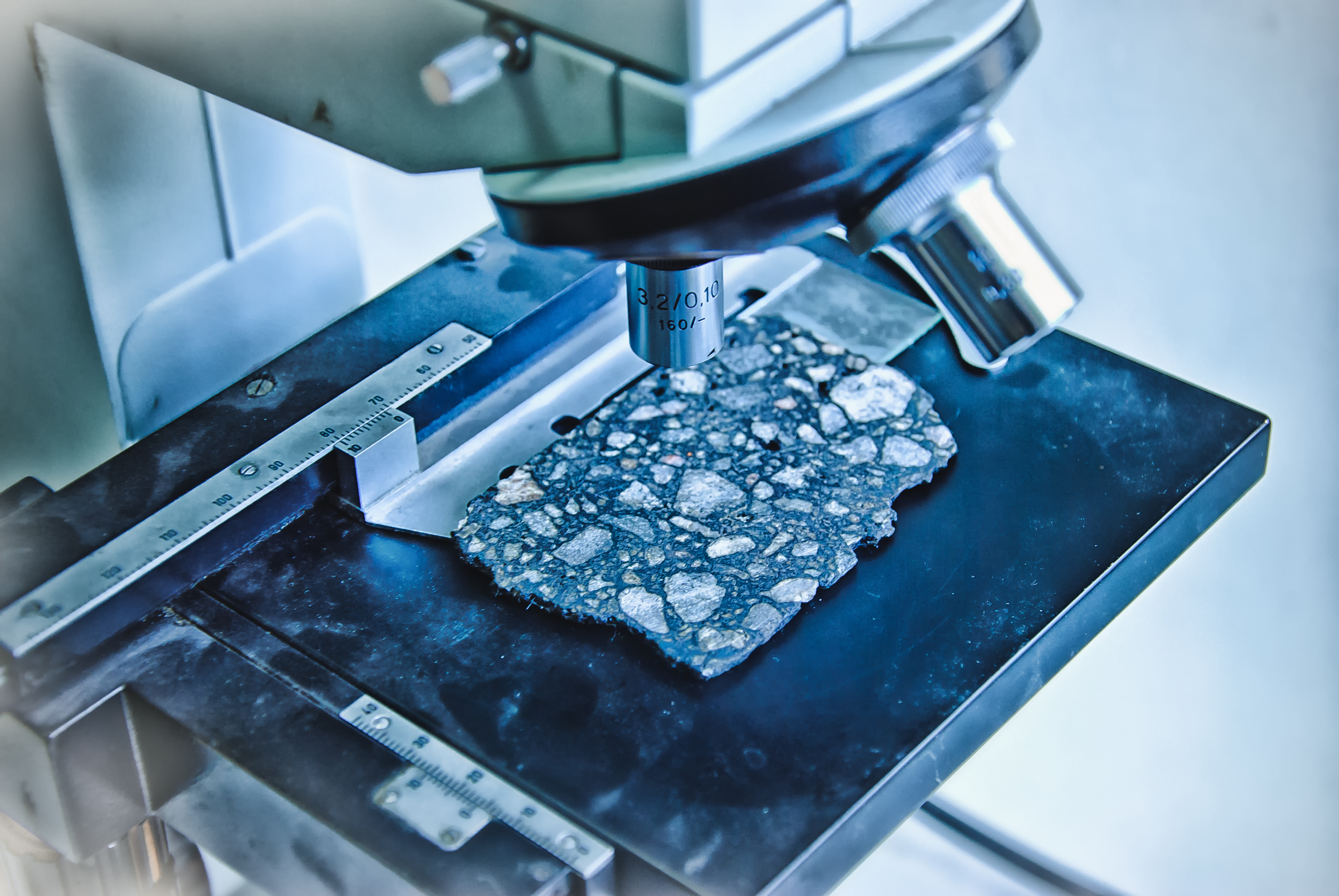

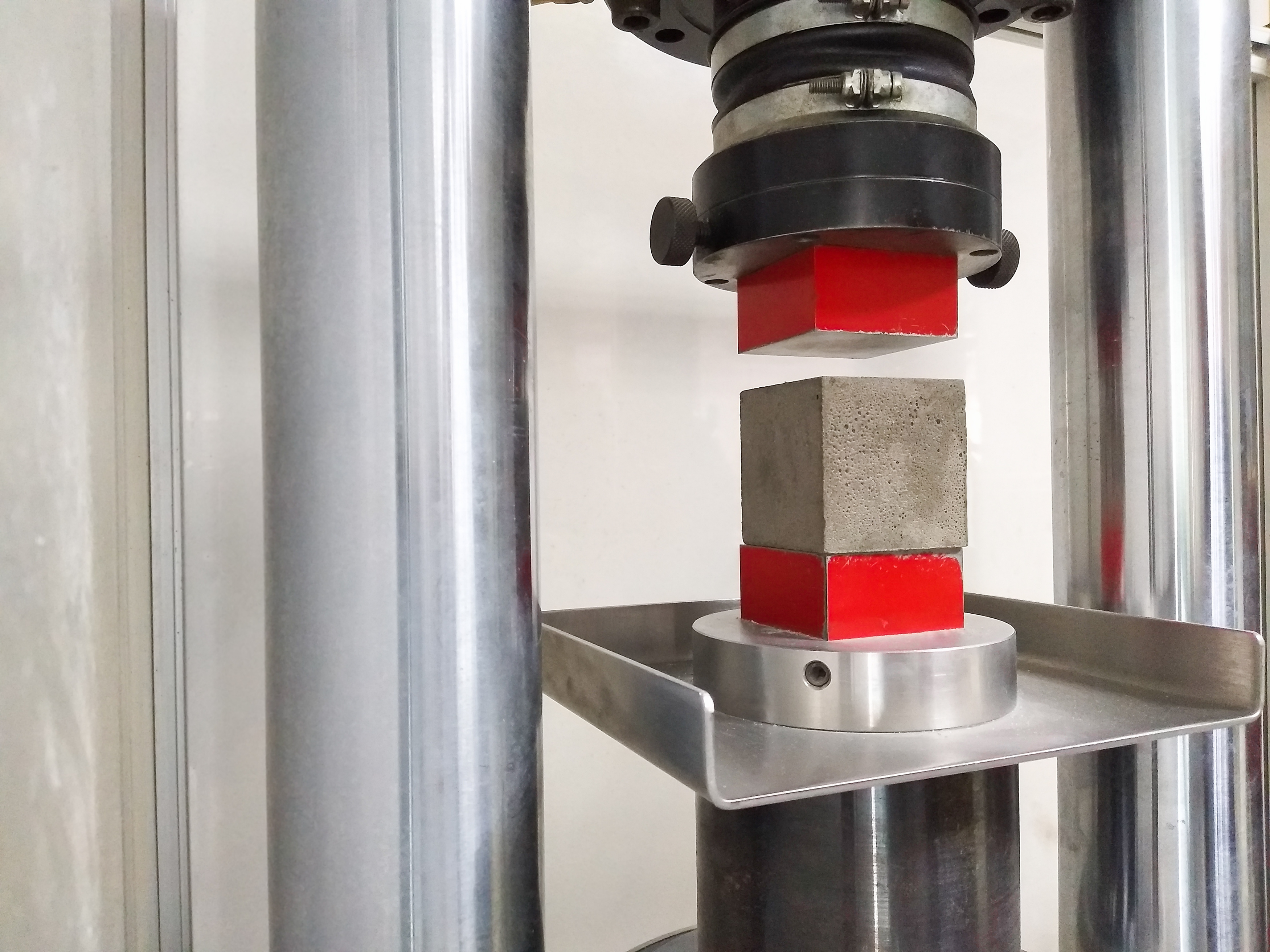

When raw materials arrive, they are inspected for quality, verified against the manufacturer's certificate, and then tested in the in-house lab for strength and composition. Our in-house quality lab performs raw material gradation, cube testing, silt checking, cube density, M35/M40 mix design check, and other tests are performed at a nationally accredited lab. Only when all of the quality criteria are met are the materials accepted on the site.

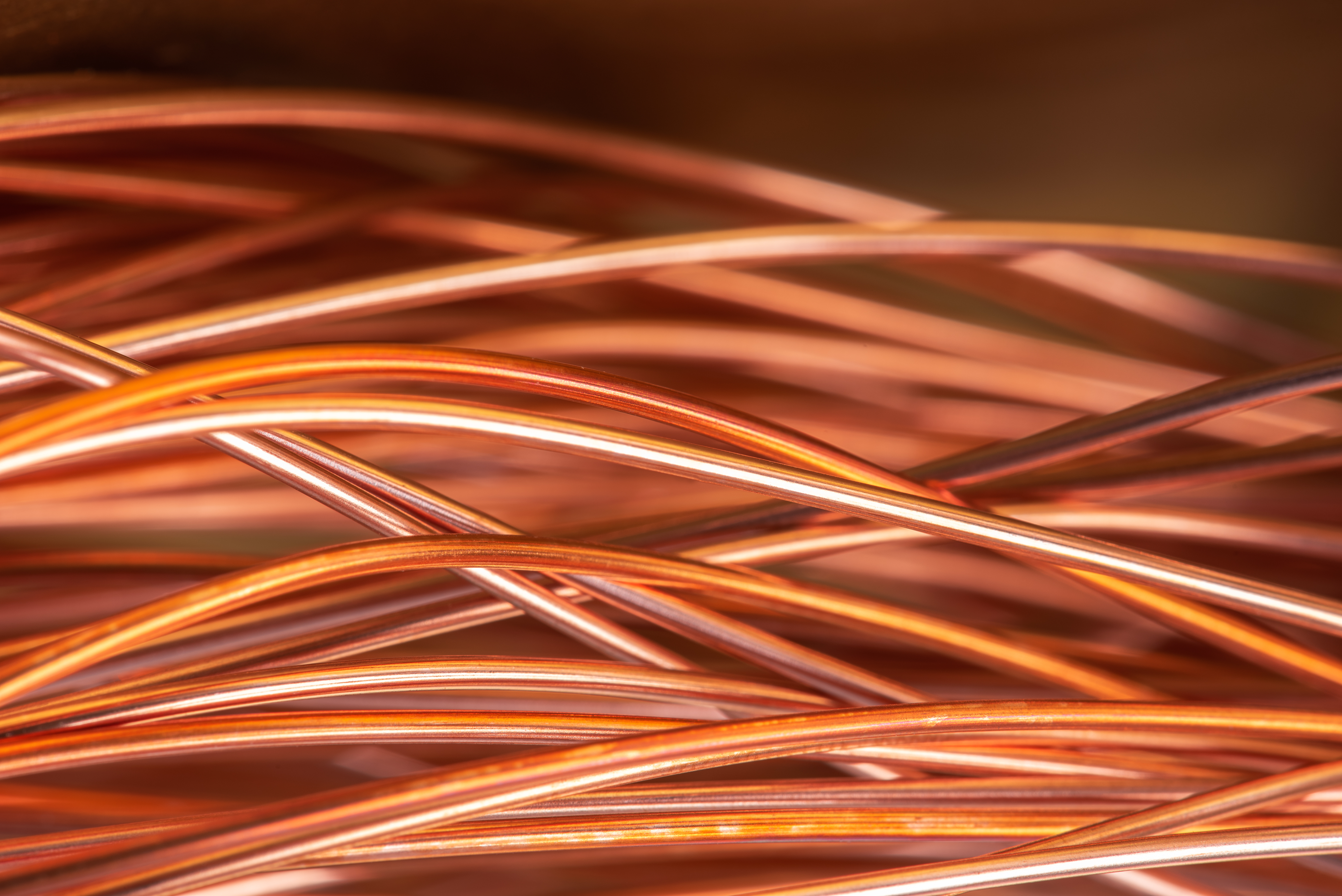

Without blinking, our managers reject the materials that do not meet the quality criteria and establish a standard of expectation for all vendors. When it comes to steel, cement, river sand, electrical, and plumbing fixtures, only the top five best brands are used for all the projects.